- Beranda

- Sains & Teknologi

Advanced NDT for Tubing Inspection

...

TS

antimabok

Advanced NDT for Tubing Inspection

Selamat pagi agan-agan inspector yang bergerak di bidang NDT

Buat agan-agan yang bergerak di bidang maintenance equipment, terutama untuk Heat Exchanger dan Boiler. Ada metode alternatif yang mungkin bukan metode baru dalam hal inspeksi tubing untuk HE dan Boiler. Metode ini dinamakan Acoustic Pulse Reflectometry.

Berikut sedikit rinciannya :

Now we are dedicated to providing Acoustic Eye Technology.

Acoustic Eye provides non-intrusive tube inspection solutions to the heat exchanger market. Utilizing breakthrough acoustic-based technology, our solutions revolutionize the way companies perform heat exchanger maintenance. With Acoustic Eye, you can test 100% of your tubes at a fraction of the time and cost of your current maintenance budget and avoid costly downtime due to failures in your mission-critical equipment.

Acoustic Eye Dolphin™

• Integrated Hardware and Software solution

• 10x faster than current offerings

• Inspects any tube

• Objective computer-based interpretation of test results

We are using the newest technology of AE Dolphin – AE G3, which advance technology and dedicated of reliable tube inspection method:

• Acoustic Eye’s breakthrough, non-invasive solution for today’s hard-to-inspect tubes up to 4” inner diameter enables ultra-fast, accurate inspection of boilers, Fin Fans and other heat exchangers, regardless of tube shape or material.

• Featuring patented Acoustic Pulse Reflectometry (APR) technology, Dolphin G3™ is an advanced, yet easy-to-use tool that overcomes the limitations of many conventional inspection techniques. With its simple operation, automated analysis and report generation, there is far less dependency on operator expertise.

• Providing reliable inspection of even the most challenging tube sizes and configurations, Acoustic Eye increases inspection cycle efficiency and operational cost savings.

Any tube size up to 4” diameter, regardless of shape or material

• Boilers, Fin Fans, other heat exchangers

• U-bends, twisted and spiral wound tubes

• Ferrous and non-ferrous metals, graphite and plastics

Ultra-fast, non-invasive inspection

• Less than 10 seconds per tube

• Fast enough for 100% inspection

• if/when needed

• Ideal for emergency situations

• No need for inventory of consumable

• probes or standards

Less expertise required

• Testing is easily performed by any operator with minimal training

• Computer-based data interpretation and report generation

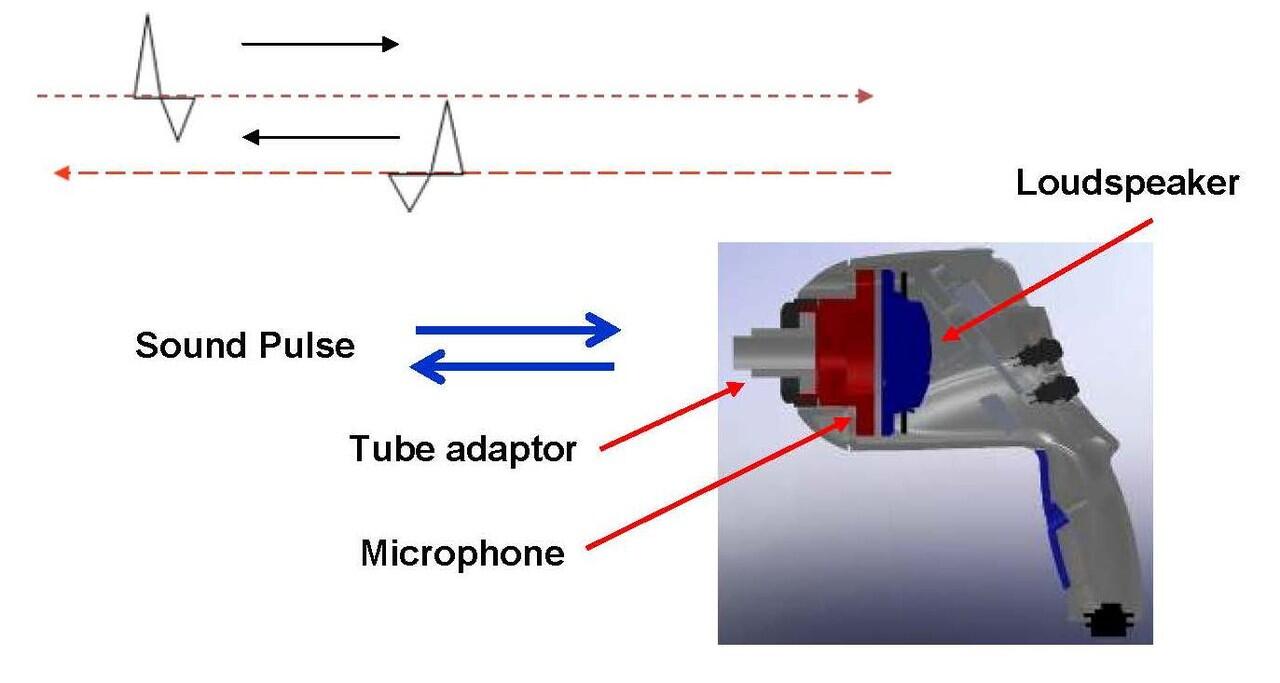

The core technology

• Probe injects an acoustic pulse down the tube

• Returned echoes generated by defects are recorded and analyzed

• A set of proprietary, patented algorithms identifies and reports exact location, type and size of inner diameter defects

Kelebihan metode APR ini dibandingkan dengan Eddy Current dan IRIS :

Kekurangan metode APR :

Gimana gan? Mungkin ada yang pernah berpengalaman dengan metode ini bisa dishare kelebihan dan kekurangan yang lain dari metode ini dan tingkat kepuasan agan-agan jika dibandingkan dengan Eddy Current dan IRIS

Salam engineer

Buat agan-agan yang bergerak di bidang maintenance equipment, terutama untuk Heat Exchanger dan Boiler. Ada metode alternatif yang mungkin bukan metode baru dalam hal inspeksi tubing untuk HE dan Boiler. Metode ini dinamakan Acoustic Pulse Reflectometry.

Berikut sedikit rinciannya :

Spoiler for Acoustic Eye:

Now we are dedicated to providing Acoustic Eye Technology.

Acoustic Eye provides non-intrusive tube inspection solutions to the heat exchanger market. Utilizing breakthrough acoustic-based technology, our solutions revolutionize the way companies perform heat exchanger maintenance. With Acoustic Eye, you can test 100% of your tubes at a fraction of the time and cost of your current maintenance budget and avoid costly downtime due to failures in your mission-critical equipment.

Acoustic Eye Dolphin™

• Integrated Hardware and Software solution

• 10x faster than current offerings

• Inspects any tube

• Objective computer-based interpretation of test results

We are using the newest technology of AE Dolphin – AE G3, which advance technology and dedicated of reliable tube inspection method:

• Acoustic Eye’s breakthrough, non-invasive solution for today’s hard-to-inspect tubes up to 4” inner diameter enables ultra-fast, accurate inspection of boilers, Fin Fans and other heat exchangers, regardless of tube shape or material.

• Featuring patented Acoustic Pulse Reflectometry (APR) technology, Dolphin G3™ is an advanced, yet easy-to-use tool that overcomes the limitations of many conventional inspection techniques. With its simple operation, automated analysis and report generation, there is far less dependency on operator expertise.

• Providing reliable inspection of even the most challenging tube sizes and configurations, Acoustic Eye increases inspection cycle efficiency and operational cost savings.

Any tube size up to 4” diameter, regardless of shape or material

• Boilers, Fin Fans, other heat exchangers

• U-bends, twisted and spiral wound tubes

• Ferrous and non-ferrous metals, graphite and plastics

Ultra-fast, non-invasive inspection

• Less than 10 seconds per tube

• Fast enough for 100% inspection

• if/when needed

• Ideal for emergency situations

• No need for inventory of consumable

• probes or standards

Less expertise required

• Testing is easily performed by any operator with minimal training

• Computer-based data interpretation and report generation

The core technology

• Probe injects an acoustic pulse down the tube

• Returned echoes generated by defects are recorded and analyzed

• A set of proprietary, patented algorithms identifies and reports exact location, type and size of inner diameter defects

Spoiler for Basic Principle:

Kelebihan metode APR ini dibandingkan dengan Eddy Current dan IRIS :

- Ultra Fast, hanya sekitar 10 detik untuk tube dengan panjang maksimal 25 meter

- Dapat dilakukan untuk berbagai konfigurasi tube (U-bend, spiral, straight, dll)

- Dapat dilakukan pada berbagai material

- Analisis dan report dapat diproses dengan cepat

Kekurangan metode APR :

- Hanya untuk inspeksi inner tube, namun sedang dalam pengembangan untuk inner dan outer tube

- Tidak dapat mendeteksi closed krack

Gimana gan? Mungkin ada yang pernah berpengalaman dengan metode ini bisa dishare kelebihan dan kekurangan yang lain dari metode ini dan tingkat kepuasan agan-agan jika dibandingkan dengan Eddy Current dan IRIS

Salam engineer

0

4K

11

Komentar yang asik ya

Mari bergabung, dapatkan informasi dan teman baru!

Sains & Teknologi

15.5KThread•11.4KAnggota

Urutkan

Terlama

Komentar yang asik ya