TS

boleroes11

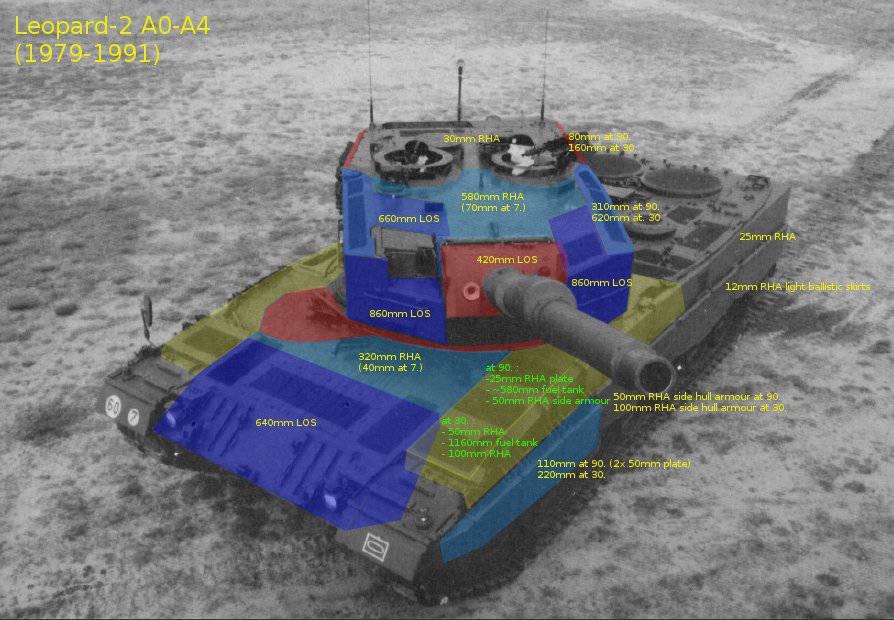

Evaluation of Armor Tank Leopard 2A)-A4.

Evaluation of armor tank Leopard 2A0-A4

Yesterday, 08:38 Print

Protection of the whole tank can be described from three perspectives:

Physical thickness of armor;

Integrity of armor protection and weak areas in the tank for 0-30 degrees from the longitudinal axis;

Know the characteristics of the special armor and its ability to protect against armor piercing ammunition and cumulative.

It is important to note that the Leopard-2 tank was born as a child of many compromises and some solutions are considered currently not very successful. They were developed in the 70s of the last century in order to achieve better fire power (the main sight placement EMES-15 into the gap between the blocks of the frontal armor to simplify the installation of optics and thermal imaging cameras are basically radar) or to achieve a better supportability and maintainability. For example, a huge gun mantle was developed to the possibility of replacing the entire gun on the battlefield without removing it from the chassis.

In the 80s and 90s when some solutions in Leopard-2A4 were incorrect regarding armor protection (against the perspective of the Soviet anti-tank weapons) program began KWS was developed deep modernization of the tank to the level of 2A5, where the most serious integrity problems were booking solved (or improved).

1) The physical thickness of the tank armor:

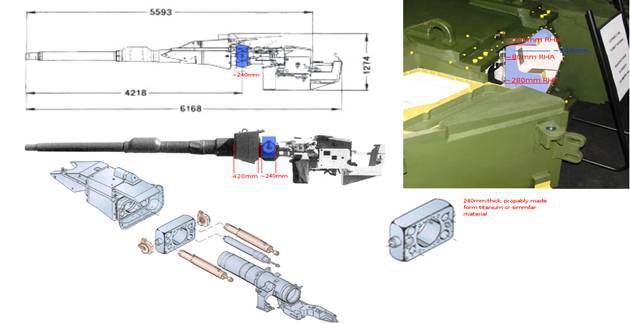

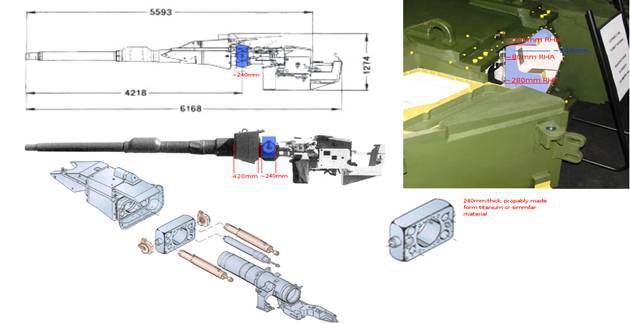

Area gun mantle result

Armored gun mask at Leopard-2A4 has a thickness of 420 mm (42 cm) and it consists of several layers. Its weight is 620 kg. After the mantle result placed hinged frame guns (in German terminology wedge), which is made of high alloy thickness. This frame "straddles" thick metal sheets which constitute the roof and the bottom of the armored turret. Boca tower covered with thick sheets of rolled homogeneous armor (RHA), in which there are thick bars (axis) for mounting the gun and mask gun at one point in the tower.

The entire area looks like

Virtually the entire layout of the armor in the zone mantle result consists of:

Block 420 mm armor + hinged frame of light alloy thickness 240 mm + sheets of rolled homogeneous armor thickness of 80 and (mostly) 230 mm. With this solution, the whole area is well protected gun mantle result from armor-piercing ammunition and cumulative unlike previous solutions, which can not survive Rockets 3BM15 or earlier BK-15. Gun mantle result Leopard-2A4 withstood the main armament of the BMP-1, 2A28 gun Thunder with shaped shells, and Putra Baby.

Reservations on the left side of the tower (charging)

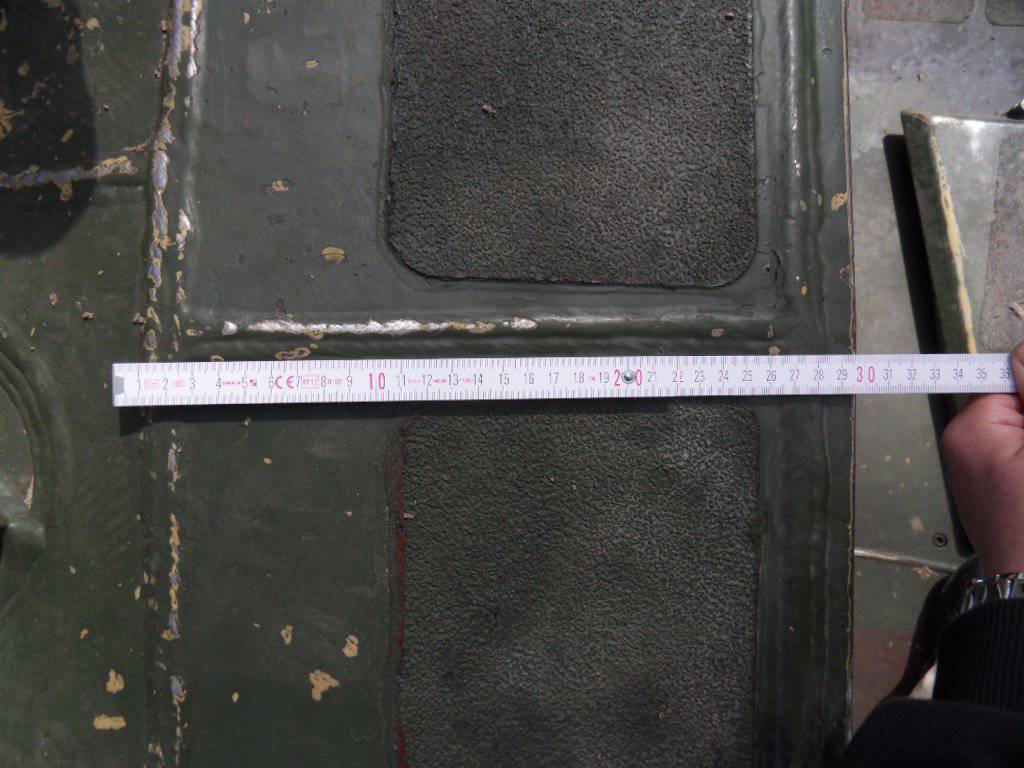

Physical thickness of the frontal armor by charging incredible (for the end of the 70s) - 860 mm. Backsheet (armor plate special recess ends) is made from a sheet of rolled homogeneous armor thickness of 60 mm from high hardness; the front sheet may have the same thickness. Between them there is a recess (approximately 740 mm) for a special armor module. This special armor module can be easily replaced by trimming the top (roof) of the sheet and replace the entire module. A similar process took place in 1991 on the tanks M1 Abrams, it took about 30 minutes for one module (one drawer with a special armor module inside).

Such a large thickness was necessary due to the specific type of special reservation known as Burlington, for this type of armor need a lot of space. 860 mm thickness was greatest in the world until the end of the 80s did not adopt Tank M1A1.

The right side of the tower (commander and gunner)

Tank commander protected armor thickness of 660 mm, a thickness of armor set right in front of his face. Currently, this area (behind the main gun EMES-15) is considered to be a weak area, but for the 80s that was enough. Armor thickness 660 mm are rare in most tanks of the time (except for M1 Abrams). But due to the use of heavier armor components could achieve a similar level of protection for the left side of the tower (by charging).

The thickness of the turret before place the arrow is the same as the left side of the turret 860 mm, but with a different layout: a first cavity in the armor for the EMES-15 and the second for the WBG-X. Therefore, the total thickness of close to 1100 mm (110 cm) including this recess.

Bok Tower in the crew compartment area

Bok Tower crew compartment protected by armor thickness of 310 mm, ie 30 degrees from the longitudinal axis of the tower it gives almost 620 mm; it was a great value in the 80s. Currently, these figures seem to be insufficient and therefore Leopard-2A5 on the sides of the tower installed modules dynamic protection NERA, and almost all of the available modernization Leopard-2A4 consists of installing additional modules in order to obtain a higher level of protection of the zone, but the overall thickness This place is doubled.

Bustle tower

Entirely bustle tower behind the crew compartment is protected only by a simple rolled homogeneous armor. This decision was taken in order to reduce weight. This is the weakest area around the tank Leopard-2, and it is impossible to correct even now. This is partly determined by the tactical tank as he fights a battle with the enemy in front of him. But now in unconventional combat all bustle tower Leopard-2 turns into a significant flaw that can be corrected only active protection systems (such as thrush, Trophy or AMAP-ADS).

Boeukladka bustles in Leopard-2A4 (of course with expelling panel) closed the armor thickness of 80 mm, ie 30 degrees to a thickness of 160 mm. Bustle tower behind closed homogeneous plate of steel with thickness of 25 mm:

Reservations roof tower

Roof of the tower Leopard-2A4 divided by line charging periscope PERI. Front part of the roof is made possible (the author is not sure) of rolled homogeneous armor thickness of 70 mm tilted 7 degrees, which gives a thickness of 580 mm. This was (as in the case with a sloping front hull) is more than enough in the 80s. But the second part, you may have a thickness of 30 mm. This part was really vulnerable to artillery shells and small caliber Cluster Munitions, and she was seriously modified when upgrading to Leopard-2 program KWS.

The frontal armor corps

The frontal armor body armor protected by a special module thickness of 640 mm. Only in its lower part, it has a smaller thickness of about 400 mm. This former thickness is more than enough for the 80s, but in the 90s the whole modernization Leopard-2 was (except German tanks) to install additional armor to protect NERA frontal hull armor.

Sloping upper sheet 40 mm thick has an inclination angle of 7 degrees (homogenous armor 320 mm). This slope sheets of high hardness alloy was more than enough in the 80s. In this case, armor-piercing ammunition and projectiles ricochet cumulative. But the appearance in 90 years with a long piercing shells core and progress in cumulative ammunition HEAT forced developers to close this area almost all modernized tanks Leopard-2 (except German) thick modules NERA (Leopard-2A5DK, Strv.122, Leopard- 2A6E/HEL, etc.).

Luke Driver 30 mm thick

Its design was flawed, the hatch was vulnerable to 30-mm anti-tank missiles and warheads, and therefore this element in the tank Leopard-2A5 has been completely redesigned. Luke Driver - this is the second weakest spot Leopard-2 tank.

Sides of the hull

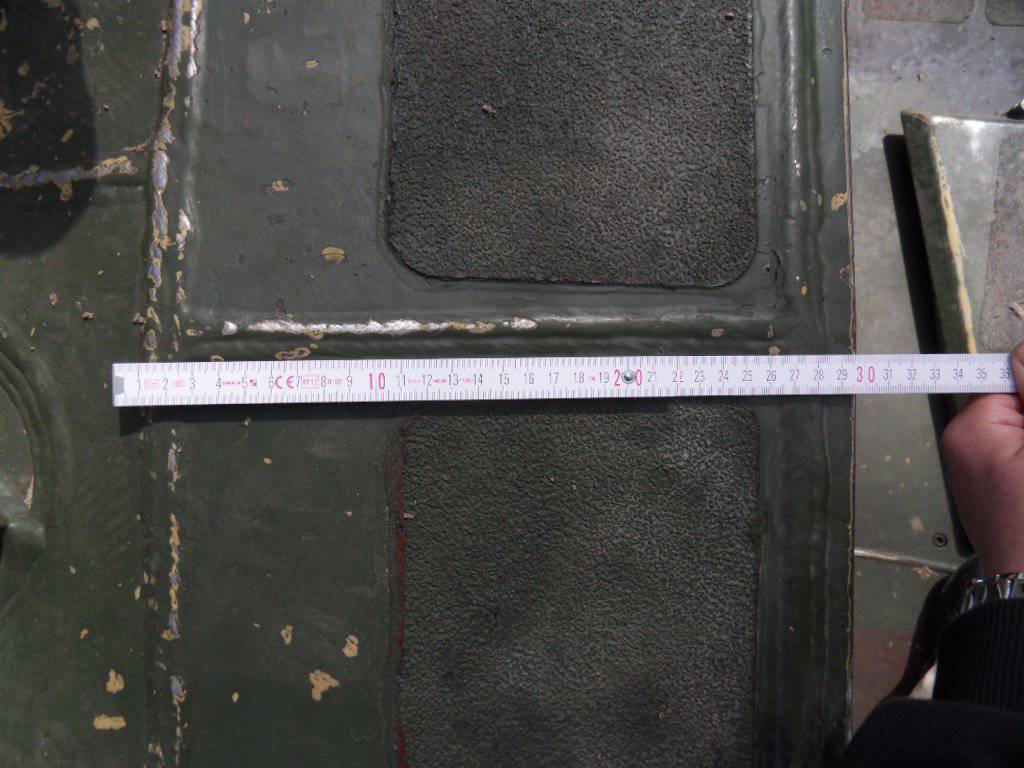

Sides of the hull Leopard-2A4 consist of three thicknesses (!).

On the right side of the driver standing list (near the hatch area) rolled homogeneous Boroni 80 mm thick, but only there.

The thickness of the hull above the crew compartment is 50 mm in the area of suspension 25 mm.

Feed case is protected by 25 mm sheets of rolled homogeneous armor.

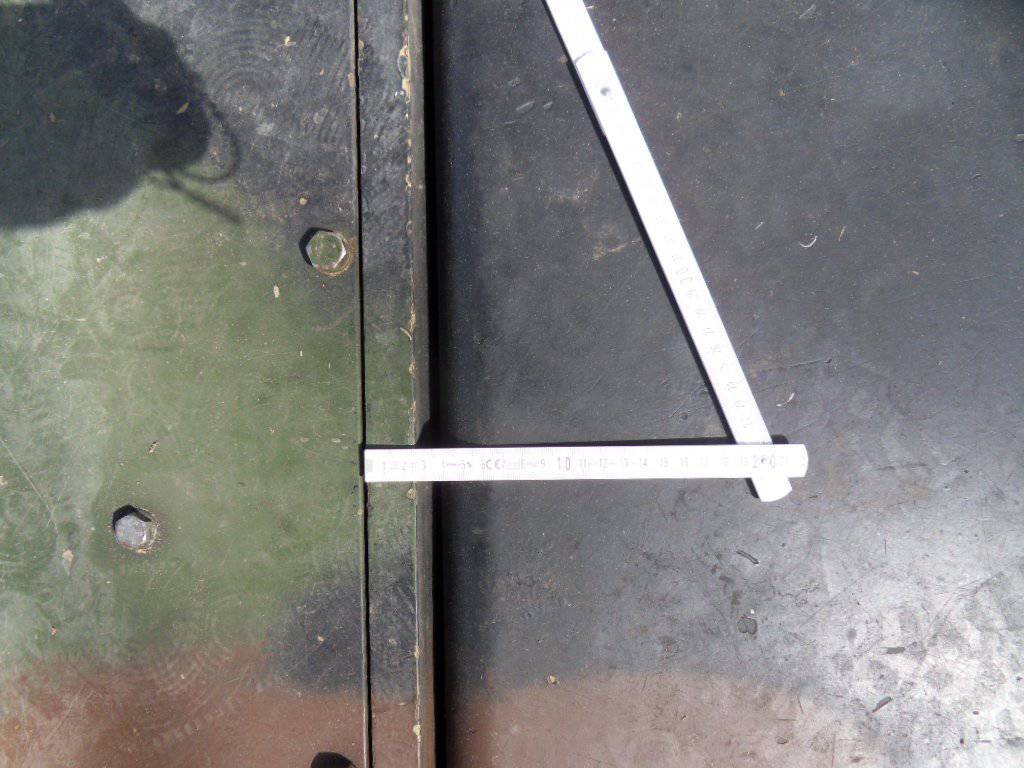

Importantly, over the tracks Leopard-2A4 protected spaced armor consisting of: the outer sheet 25 mm thick, a fuel tank of about 580 mm thickness and the actual thickness of the armor shell 50 mm.

According to the developers of the Israeli Merkava tanks of fuel are 70 mm armor plate thickness of 10 mm. That is 580 mm fuel work (against HEAT projectile HEAT) as a sheet 80 mm thick armor. This decision was the best for the tilt of 30 degrees, it allows you to have a sufficient number of layers and enough room to stop grenade RPG-7.

Under the fuel tank side of the tank Leopard-2A4 protected by armor body 50 mm thick and light side screens 12 mm thick

Boeukladka housing is protected from both sides, only leaf thickness of 50 mm, but also heavy bulletproof screen thickness of 110 mm

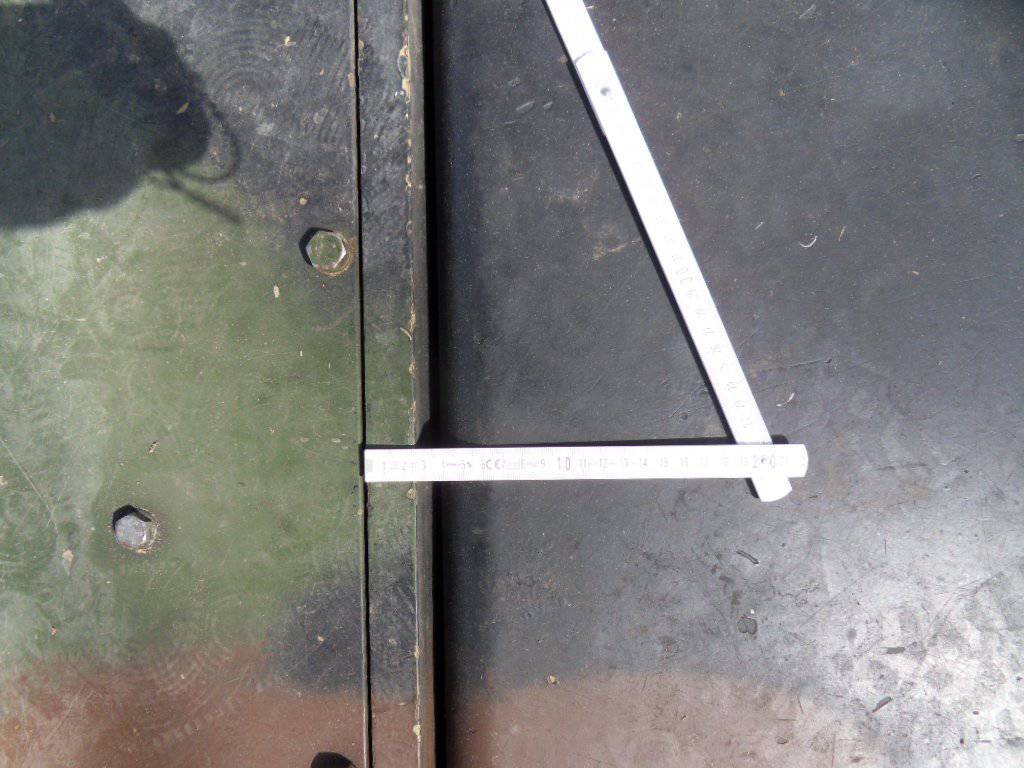

Each module weighs more than 110 kg and consists of two 50-mm sheet of rolled homogeneous armor separated by an air gap.

So, under the protection board tracks the top line is 100 mm sheets RHA + clearance + 50 mm side sheet.

For this gives 30 degrees sheets RHA 200 mm + clearance + 100mm board sheet. These sheets of high-strength steel armor was sufficient at the end of the 70s to stop most of the light anti-tank shells and old artillery shells.

Currently, such protection is not enough, and almost all of modernization leopard-2 regarding conducting asymmetric warfare is new, much thicker bulletproof screens almost the entire length of the hull sides.

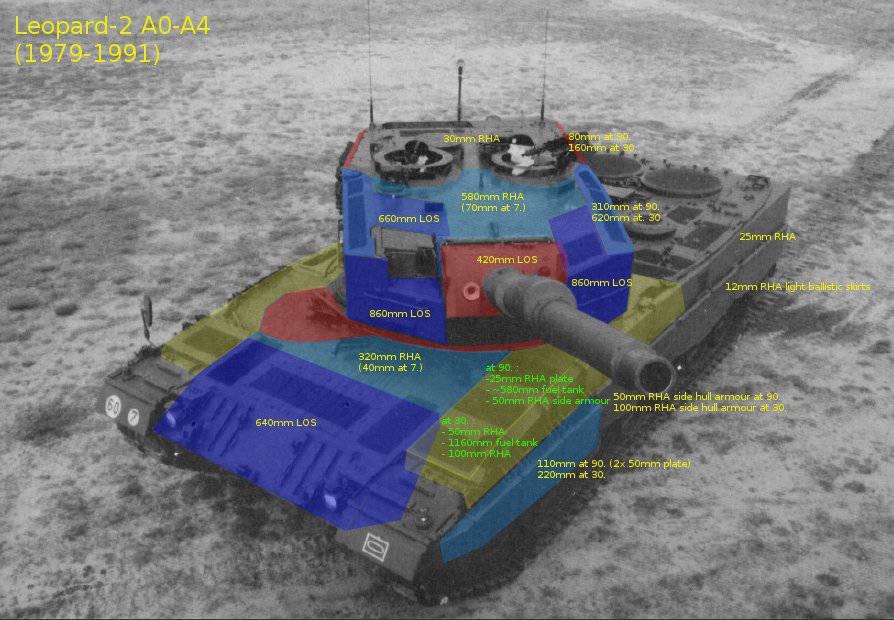

Physical thickness of armor as a whole

Integrity of armor protection and the location of weak zones for the tank for 0-30 degrees from the longitudinal axis

For Leopard-2A4 tank armor integrity is a secondary factor. Absolute priority for developers were fire power, mobility, supportability and maintainability. Many of the solutions for the Leopard-2 are given as examples of weaknesses or poor integrity (continuity) of armor.

The most often mentioned disadvantages are:

Very large gun mantle result

Armor unit for the main gun EMES-15

No special armor bustles tower

In fact, only the last example can really be called a weak point, but only for the sides or 15-30 degrees from the longitudinal axis. Developers Leopard-2 stopped for such a decision in order to reduce weight.

Armor unit for the main gun EMES-15 can not be called a weak link for the 80s. Why? Because the thickness in this place 660 mm, which is exactly equal to the thickness of the frontal armor of most tanks 80s:

In tanks T-64A and T-64B thickness of the frontal armor of the tower is a maximum of 485 - 496 mm (source: http://btvt.narod.ru/raznoe/bulat-le...s/image011.jpg) is less than 660 mm thick armor .

In the T-80B, the thickness of the frontal armor lies between 560 and 640 mm (30 degrees to 530 mm)

In the case of tank T-80U turret thickness generally in the range of 600 mm (source: http://btvt.narod.ru/raznoe/bulat-le...s/image011.jpg http://btvt.narod.ru/4 / bars_leopard/80-1.jpg)

Which again is less.

The frontal armor from T-72B is 600 to 750 mm, 30 degrees is 600 - 680 mm, which is almost equal to the thickness of 660 mm at the Leopard-2 tank.

For this reason, the thickness of the armor unit for 660 mm tank Leopard-2A4 is not a weak point in comparison with the values of 500 - 600 - 680 mm for Soviet tanks.

But in the 80s and 90s became available to new ATGM and armor-piercing projectiles, but there were also new and improved tower at the Soviet tanks (obekt.187, obekt.478BE, etc.). Then it became clear that this area really is a serious drawback. For this reason, frontal armor was completely replaced in the framework of KWS, and now the armor on the left and right sides of the same thickness (~ 860 mm).

Mantle result Gun Tank Leopard-2 has a width of 93 cm, which is comparable to the size of most bronemasok Soviet tanks. This value for them is approximately 83 - 86 cm Therefore, these two values for the Western and Soviet tanks can be compared.

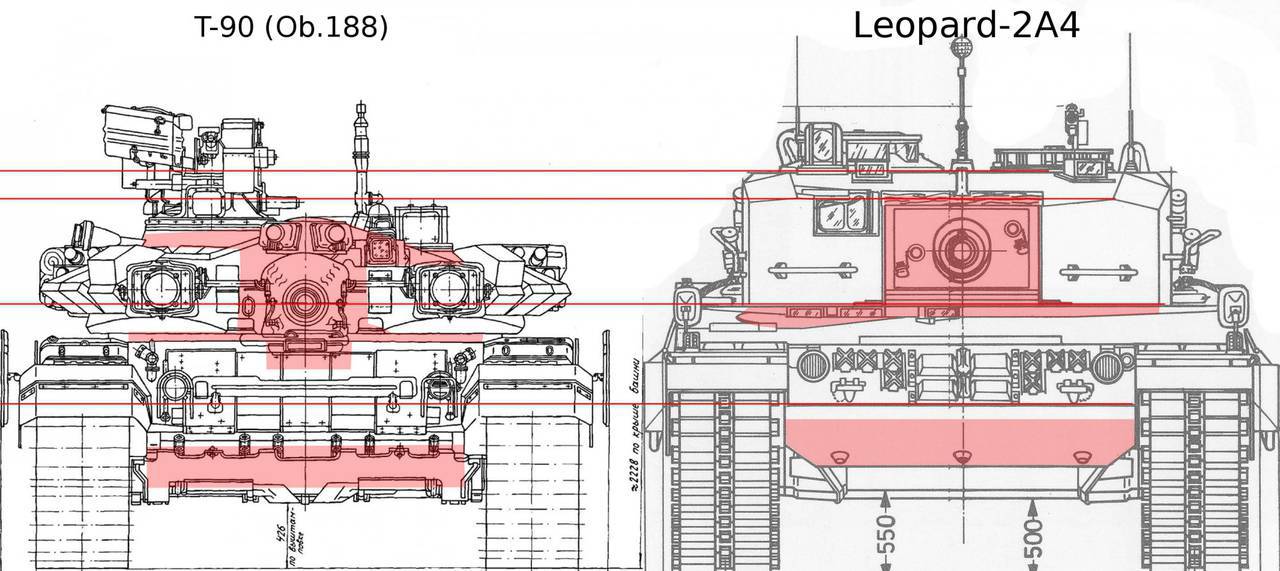

For these reasons, in the 80s and early 90s (before the objects 478BE and 188A1) weaknesses for Leopard-2A4 tanks and most Soviet tanks were comparable

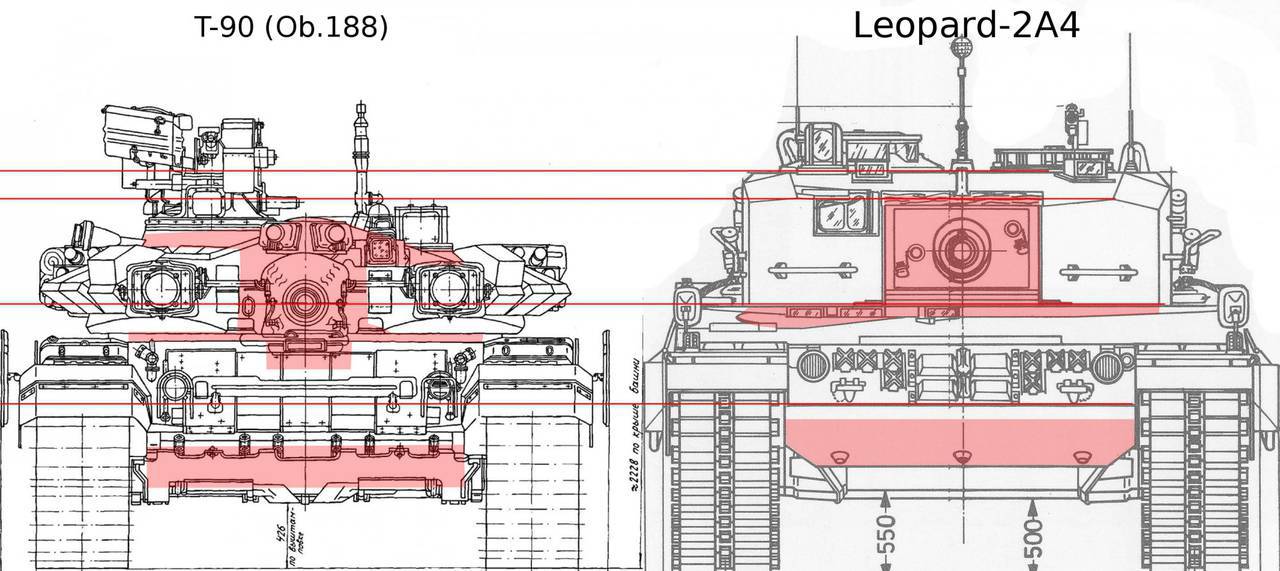

Weak zones can be compared in Figure

Of course, in comparison with the tank T-80UD Leopard-2A4, apparently has a much worse performance.

In fact, the tower Leopard-2A4 may be comparable in both areas: integrity armor, weak areas and hazards (ammunition, oil pumps, etc.) on the picture

The third aspect. Know the characteristics of the special armor and its ability to protect against armor piercing ammunition and cumulative

In the case of special armor we do not know the details. Through research Paweł Przeździecki in the UK, we can describe some general features of the type of armor Burlington (burlington):

British armor was made as a kind of "armor-bulkhead" with gaps between the layers; as a sandwich - two thin steel sheet and between the non-metallic layer.

In its configuration abroad 60/70 years of armor "burlington" against cumulative warheads were 2-3 times better compared to monolithic steel armor of the same weight and had similar resistance against armor-piercing shells.

The mass efficiency of new variants of booking (burlington - multilayer) increased by 1.3 - 1.5 times against armor piercing cores and more than 3 times against cumulative projectiles.

Translation Part 1:

In the second half of the '70s began to pay more attention to protection against kinetic munitions. "Biscuits" (burlington - multilayer), designed for tank Chieftain mk 5/2, could stop a 105-mm armor-piercing shell with virtually zero distance or 120-mm armor-piercing of the race 1200 - 1300 meters. In 1975, the U.S. has been successfully tested "Americanized" armor against 152-mm armor-piercing ammunition and XM578 cumulative projectiles (unnamed caliber), which represented a typical ammunition 80s. More challenging was the struggle with modern subcaliber ammunition. During the tripartite test weapons (United Kingdom, Germany, USA) was shot dead one piercing shells from the German 120-mm smoothbore gun, he struck his armor type «Cobham» at a rate simulating hit with 6000 sq. heavier armor variant, however, was broken from a distance of only 200 m

Translation Part 2:

Later, the designers were able to increase armor protection modules. In the early 70-ies reported: "All the technical problems concerning armor, namely resistance to multiple attacks, have been overcome. For example, the first module into the housing front withstood 9 cumulative attacks (including a caliber of 152 5 mm and 4 mm 127 gauge). Second (unit burlington - multiwall) stopped 120 mm projectile with crushes warhead HESH, followed by multiple blows cumulative 127-mm shells. The third module (burlington - multiwall) "experienced" 3 armor piercing projectile 105 mm caliber and then attack (more than two) cumulative projectiles caliber 127 mm. " In July 1970 "biscuit» No. 4 (burlington) with the front sheet of rolled homogeneous armor thickness of 50 mm survived multiple hits: 105 mm projectile with "zero distance", 152 mm warhead Shillelagh, two cumulative diameter of 152 mm, and finally a 120-mm armor-piercing with distance 1300 m ability to withstand multiple attacks has become an important feature of the armor of the "Burlington."

The above information is the latest information about the armor of the "Burlington". In the case of tank Leopard-2A4 we can assume or estimate armor protection. Several methods of evaluation of armor and most of them give similar results in the two groups of options (worst and best); average between the two options gives the following results: For the tower: 860-760-620 mm thickness without tilt (front of the tower, the front of the tower to 30 degrees, the sides of the tower to 30 degrees) against armor-piercing (in mm rolled homogeneous armor - RHA) 570-510-410 mm against cumulative HEAT (in mm RHA) 910-810-640 mm body thickness of 640 mm without tilt: approximately 500 mm armor-piercing against and 700 mm versus cumulative HEAT These values should be compared with the level of ammunition 80 -ies: Broneprobivanie achievable (E) at 2000 m; broneprobivanie guaranteed (D) 2000 m for typical piercing shells: 3BM-26: W: 440mm D: 400mm ~ 3BM-29: W: 450mm D: 410mm ~ 3BM-32: W: 500mm D: ~ 460mm 3BM-42: W: 460mm D: ~ 430 mm and typical cumulative (HEAT) shells: 9M111M (1983) broneprobivanie 600 mm RHA; 9M120 (1985) 800 mm broneprobivanie RAH; 9M128 (1985) 650 mm RHA broneprobivanie , 9M119M Invar (1992?) broneprobivanie 700-750 mm RHA Cornet (1993) broneprobivanie 1100mm RHA, As you can see, theoretically reservation tank Leopard-2A4 was good enough for the 80s, at least, the front of the turret and hull . It's all about being evaluated for a distance of 1000 meters. On the other hand, the Soviet tanks, protected by heavy ERA Contact 5 were serious opponent for Western tanks.

Based on site btvt.narod.ru

===========================

Yesterday, 08:38 Print

Protection of the whole tank can be described from three perspectives:

Physical thickness of armor;

Integrity of armor protection and weak areas in the tank for 0-30 degrees from the longitudinal axis;

Know the characteristics of the special armor and its ability to protect against armor piercing ammunition and cumulative.

It is important to note that the Leopard-2 tank was born as a child of many compromises and some solutions are considered currently not very successful. They were developed in the 70s of the last century in order to achieve better fire power (the main sight placement EMES-15 into the gap between the blocks of the frontal armor to simplify the installation of optics and thermal imaging cameras are basically radar) or to achieve a better supportability and maintainability. For example, a huge gun mantle was developed to the possibility of replacing the entire gun on the battlefield without removing it from the chassis.

In the 80s and 90s when some solutions in Leopard-2A4 were incorrect regarding armor protection (against the perspective of the Soviet anti-tank weapons) program began KWS was developed deep modernization of the tank to the level of 2A5, where the most serious integrity problems were booking solved (or improved).

1) The physical thickness of the tank armor:

Area gun mantle result

Armored gun mask at Leopard-2A4 has a thickness of 420 mm (42 cm) and it consists of several layers. Its weight is 620 kg. After the mantle result placed hinged frame guns (in German terminology wedge), which is made of high alloy thickness. This frame "straddles" thick metal sheets which constitute the roof and the bottom of the armored turret. Boca tower covered with thick sheets of rolled homogeneous armor (RHA), in which there are thick bars (axis) for mounting the gun and mask gun at one point in the tower.

The entire area looks like

Virtually the entire layout of the armor in the zone mantle result consists of:

Block 420 mm armor + hinged frame of light alloy thickness 240 mm + sheets of rolled homogeneous armor thickness of 80 and (mostly) 230 mm. With this solution, the whole area is well protected gun mantle result from armor-piercing ammunition and cumulative unlike previous solutions, which can not survive Rockets 3BM15 or earlier BK-15. Gun mantle result Leopard-2A4 withstood the main armament of the BMP-1, 2A28 gun Thunder with shaped shells, and Putra Baby.

Reservations on the left side of the tower (charging)

Physical thickness of the frontal armor by charging incredible (for the end of the 70s) - 860 mm. Backsheet (armor plate special recess ends) is made from a sheet of rolled homogeneous armor thickness of 60 mm from high hardness; the front sheet may have the same thickness. Between them there is a recess (approximately 740 mm) for a special armor module. This special armor module can be easily replaced by trimming the top (roof) of the sheet and replace the entire module. A similar process took place in 1991 on the tanks M1 Abrams, it took about 30 minutes for one module (one drawer with a special armor module inside).

Such a large thickness was necessary due to the specific type of special reservation known as Burlington, for this type of armor need a lot of space. 860 mm thickness was greatest in the world until the end of the 80s did not adopt Tank M1A1.

The right side of the tower (commander and gunner)

Tank commander protected armor thickness of 660 mm, a thickness of armor set right in front of his face. Currently, this area (behind the main gun EMES-15) is considered to be a weak area, but for the 80s that was enough. Armor thickness 660 mm are rare in most tanks of the time (except for M1 Abrams). But due to the use of heavier armor components could achieve a similar level of protection for the left side of the tower (by charging).

The thickness of the turret before place the arrow is the same as the left side of the turret 860 mm, but with a different layout: a first cavity in the armor for the EMES-15 and the second for the WBG-X. Therefore, the total thickness of close to 1100 mm (110 cm) including this recess.

Bok Tower in the crew compartment area

Bok Tower crew compartment protected by armor thickness of 310 mm, ie 30 degrees from the longitudinal axis of the tower it gives almost 620 mm; it was a great value in the 80s. Currently, these figures seem to be insufficient and therefore Leopard-2A5 on the sides of the tower installed modules dynamic protection NERA, and almost all of the available modernization Leopard-2A4 consists of installing additional modules in order to obtain a higher level of protection of the zone, but the overall thickness This place is doubled.

Bustle tower

Entirely bustle tower behind the crew compartment is protected only by a simple rolled homogeneous armor. This decision was taken in order to reduce weight. This is the weakest area around the tank Leopard-2, and it is impossible to correct even now. This is partly determined by the tactical tank as he fights a battle with the enemy in front of him. But now in unconventional combat all bustle tower Leopard-2 turns into a significant flaw that can be corrected only active protection systems (such as thrush, Trophy or AMAP-ADS).

Boeukladka bustles in Leopard-2A4 (of course with expelling panel) closed the armor thickness of 80 mm, ie 30 degrees to a thickness of 160 mm. Bustle tower behind closed homogeneous plate of steel with thickness of 25 mm:

Reservations roof tower

Roof of the tower Leopard-2A4 divided by line charging periscope PERI. Front part of the roof is made possible (the author is not sure) of rolled homogeneous armor thickness of 70 mm tilted 7 degrees, which gives a thickness of 580 mm. This was (as in the case with a sloping front hull) is more than enough in the 80s. But the second part, you may have a thickness of 30 mm. This part was really vulnerable to artillery shells and small caliber Cluster Munitions, and she was seriously modified when upgrading to Leopard-2 program KWS.

The frontal armor corps

The frontal armor body armor protected by a special module thickness of 640 mm. Only in its lower part, it has a smaller thickness of about 400 mm. This former thickness is more than enough for the 80s, but in the 90s the whole modernization Leopard-2 was (except German tanks) to install additional armor to protect NERA frontal hull armor.

Sloping upper sheet 40 mm thick has an inclination angle of 7 degrees (homogenous armor 320 mm). This slope sheets of high hardness alloy was more than enough in the 80s. In this case, armor-piercing ammunition and projectiles ricochet cumulative. But the appearance in 90 years with a long piercing shells core and progress in cumulative ammunition HEAT forced developers to close this area almost all modernized tanks Leopard-2 (except German) thick modules NERA (Leopard-2A5DK, Strv.122, Leopard- 2A6E/HEL, etc.).

Luke Driver 30 mm thick

Its design was flawed, the hatch was vulnerable to 30-mm anti-tank missiles and warheads, and therefore this element in the tank Leopard-2A5 has been completely redesigned. Luke Driver - this is the second weakest spot Leopard-2 tank.

Sides of the hull

Sides of the hull Leopard-2A4 consist of three thicknesses (!).

On the right side of the driver standing list (near the hatch area) rolled homogeneous Boroni 80 mm thick, but only there.

The thickness of the hull above the crew compartment is 50 mm in the area of suspension 25 mm.

Feed case is protected by 25 mm sheets of rolled homogeneous armor.

Importantly, over the tracks Leopard-2A4 protected spaced armor consisting of: the outer sheet 25 mm thick, a fuel tank of about 580 mm thickness and the actual thickness of the armor shell 50 mm.

According to the developers of the Israeli Merkava tanks of fuel are 70 mm armor plate thickness of 10 mm. That is 580 mm fuel work (against HEAT projectile HEAT) as a sheet 80 mm thick armor. This decision was the best for the tilt of 30 degrees, it allows you to have a sufficient number of layers and enough room to stop grenade RPG-7.

Under the fuel tank side of the tank Leopard-2A4 protected by armor body 50 mm thick and light side screens 12 mm thick

Boeukladka housing is protected from both sides, only leaf thickness of 50 mm, but also heavy bulletproof screen thickness of 110 mm

Each module weighs more than 110 kg and consists of two 50-mm sheet of rolled homogeneous armor separated by an air gap.

So, under the protection board tracks the top line is 100 mm sheets RHA + clearance + 50 mm side sheet.

For this gives 30 degrees sheets RHA 200 mm + clearance + 100mm board sheet. These sheets of high-strength steel armor was sufficient at the end of the 70s to stop most of the light anti-tank shells and old artillery shells.

Currently, such protection is not enough, and almost all of modernization leopard-2 regarding conducting asymmetric warfare is new, much thicker bulletproof screens almost the entire length of the hull sides.

Physical thickness of armor as a whole

Integrity of armor protection and the location of weak zones for the tank for 0-30 degrees from the longitudinal axis

For Leopard-2A4 tank armor integrity is a secondary factor. Absolute priority for developers were fire power, mobility, supportability and maintainability. Many of the solutions for the Leopard-2 are given as examples of weaknesses or poor integrity (continuity) of armor.

The most often mentioned disadvantages are:

Very large gun mantle result

Armor unit for the main gun EMES-15

No special armor bustles tower

In fact, only the last example can really be called a weak point, but only for the sides or 15-30 degrees from the longitudinal axis. Developers Leopard-2 stopped for such a decision in order to reduce weight.

Armor unit for the main gun EMES-15 can not be called a weak link for the 80s. Why? Because the thickness in this place 660 mm, which is exactly equal to the thickness of the frontal armor of most tanks 80s:

In tanks T-64A and T-64B thickness of the frontal armor of the tower is a maximum of 485 - 496 mm (source: http://btvt.narod.ru/raznoe/bulat-le...s/image011.jpg) is less than 660 mm thick armor .

In the T-80B, the thickness of the frontal armor lies between 560 and 640 mm (30 degrees to 530 mm)

In the case of tank T-80U turret thickness generally in the range of 600 mm (source: http://btvt.narod.ru/raznoe/bulat-le...s/image011.jpg http://btvt.narod.ru/4 / bars_leopard/80-1.jpg)

Which again is less.

The frontal armor from T-72B is 600 to 750 mm, 30 degrees is 600 - 680 mm, which is almost equal to the thickness of 660 mm at the Leopard-2 tank.

For this reason, the thickness of the armor unit for 660 mm tank Leopard-2A4 is not a weak point in comparison with the values of 500 - 600 - 680 mm for Soviet tanks.

But in the 80s and 90s became available to new ATGM and armor-piercing projectiles, but there were also new and improved tower at the Soviet tanks (obekt.187, obekt.478BE, etc.). Then it became clear that this area really is a serious drawback. For this reason, frontal armor was completely replaced in the framework of KWS, and now the armor on the left and right sides of the same thickness (~ 860 mm).

Mantle result Gun Tank Leopard-2 has a width of 93 cm, which is comparable to the size of most bronemasok Soviet tanks. This value for them is approximately 83 - 86 cm Therefore, these two values for the Western and Soviet tanks can be compared.

For these reasons, in the 80s and early 90s (before the objects 478BE and 188A1) weaknesses for Leopard-2A4 tanks and most Soviet tanks were comparable

Weak zones can be compared in Figure

Of course, in comparison with the tank T-80UD Leopard-2A4, apparently has a much worse performance.

In fact, the tower Leopard-2A4 may be comparable in both areas: integrity armor, weak areas and hazards (ammunition, oil pumps, etc.) on the picture

The third aspect. Know the characteristics of the special armor and its ability to protect against armor piercing ammunition and cumulative

In the case of special armor we do not know the details. Through research Paweł Przeździecki in the UK, we can describe some general features of the type of armor Burlington (burlington):

British armor was made as a kind of "armor-bulkhead" with gaps between the layers; as a sandwich - two thin steel sheet and between the non-metallic layer.

In its configuration abroad 60/70 years of armor "burlington" against cumulative warheads were 2-3 times better compared to monolithic steel armor of the same weight and had similar resistance against armor-piercing shells.

The mass efficiency of new variants of booking (burlington - multilayer) increased by 1.3 - 1.5 times against armor piercing cores and more than 3 times against cumulative projectiles.

Translation Part 1:

In the second half of the '70s began to pay more attention to protection against kinetic munitions. "Biscuits" (burlington - multilayer), designed for tank Chieftain mk 5/2, could stop a 105-mm armor-piercing shell with virtually zero distance or 120-mm armor-piercing of the race 1200 - 1300 meters. In 1975, the U.S. has been successfully tested "Americanized" armor against 152-mm armor-piercing ammunition and XM578 cumulative projectiles (unnamed caliber), which represented a typical ammunition 80s. More challenging was the struggle with modern subcaliber ammunition. During the tripartite test weapons (United Kingdom, Germany, USA) was shot dead one piercing shells from the German 120-mm smoothbore gun, he struck his armor type «Cobham» at a rate simulating hit with 6000 sq. heavier armor variant, however, was broken from a distance of only 200 m

Translation Part 2:

Later, the designers were able to increase armor protection modules. In the early 70-ies reported: "All the technical problems concerning armor, namely resistance to multiple attacks, have been overcome. For example, the first module into the housing front withstood 9 cumulative attacks (including a caliber of 152 5 mm and 4 mm 127 gauge). Second (unit burlington - multiwall) stopped 120 mm projectile with crushes warhead HESH, followed by multiple blows cumulative 127-mm shells. The third module (burlington - multiwall) "experienced" 3 armor piercing projectile 105 mm caliber and then attack (more than two) cumulative projectiles caliber 127 mm. " In July 1970 "biscuit» No. 4 (burlington) with the front sheet of rolled homogeneous armor thickness of 50 mm survived multiple hits: 105 mm projectile with "zero distance", 152 mm warhead Shillelagh, two cumulative diameter of 152 mm, and finally a 120-mm armor-piercing with distance 1300 m ability to withstand multiple attacks has become an important feature of the armor of the "Burlington."

The above information is the latest information about the armor of the "Burlington". In the case of tank Leopard-2A4 we can assume or estimate armor protection. Several methods of evaluation of armor and most of them give similar results in the two groups of options (worst and best); average between the two options gives the following results: For the tower: 860-760-620 mm thickness without tilt (front of the tower, the front of the tower to 30 degrees, the sides of the tower to 30 degrees) against armor-piercing (in mm rolled homogeneous armor - RHA) 570-510-410 mm against cumulative HEAT (in mm RHA) 910-810-640 mm body thickness of 640 mm without tilt: approximately 500 mm armor-piercing against and 700 mm versus cumulative HEAT These values should be compared with the level of ammunition 80 -ies: Broneprobivanie achievable (E) at 2000 m; broneprobivanie guaranteed (D) 2000 m for typical piercing shells: 3BM-26: W: 440mm D: 400mm ~ 3BM-29: W: 450mm D: 410mm ~ 3BM-32: W: 500mm D: ~ 460mm 3BM-42: W: 460mm D: ~ 430 mm and typical cumulative (HEAT) shells: 9M111M (1983) broneprobivanie 600 mm RHA; 9M120 (1985) 800 mm broneprobivanie RAH; 9M128 (1985) 650 mm RHA broneprobivanie , 9M119M Invar (1992?) broneprobivanie 700-750 mm RHA Cornet (1993) broneprobivanie 1100mm RHA, As you can see, theoretically reservation tank Leopard-2A4 was good enough for the 80s, at least, the front of the turret and hull . It's all about being evaluated for a distance of 1000 meters. On the other hand, the Soviet tanks, protected by heavy ERA Contact 5 were serious opponent for Western tanks.

Based on site btvt.narod.ru

===========================

0

16.6K

4

Thread Digembok

Mari bergabung, dapatkan informasi dan teman baru!

Militer

20KThread•6.8KAnggota

Terlama

Thread Digembok